Double-Chamber Vacuum Machine | Commercial Large-Scale Food & Seafood Vacuum Sealer | Dual-Hopper Grooved Cooked Food Packaging & Sealing Machine

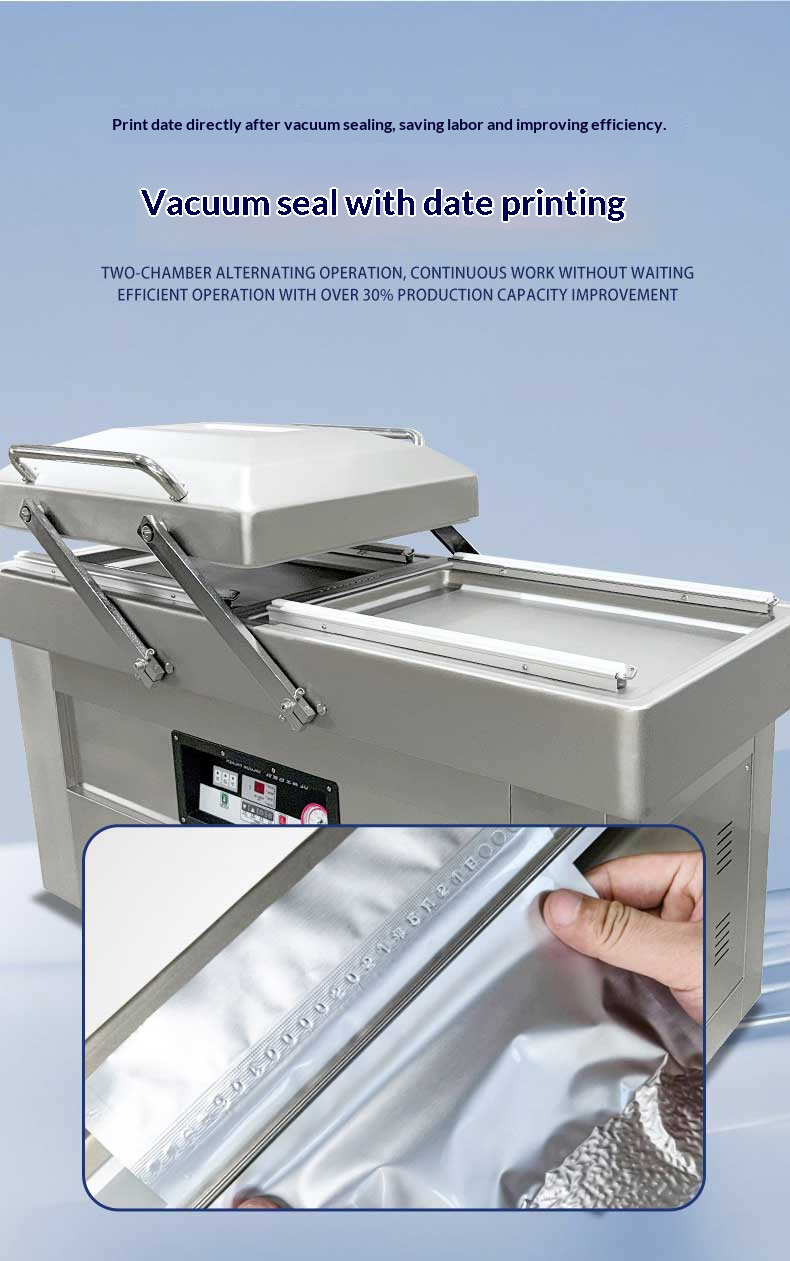

The double-chamber grooved vacuum packaging machine uses a vacuum pump to extract air from the bag to create a vacuum state, and then seals the bag via a heat sealer. It is mainly composed of a vacuum pump, vacuum chambers, a heat sealer and an electronic control system. The specific working steps are as follows: place the food into the bag and put it in the vacuum chamber, press the start button, and the vacuum pump will extract air from the bag; when the preset vacuum level is reached, the heat sealer will perform the sealing operation, and the machine will stop automatically after sealing is completed.

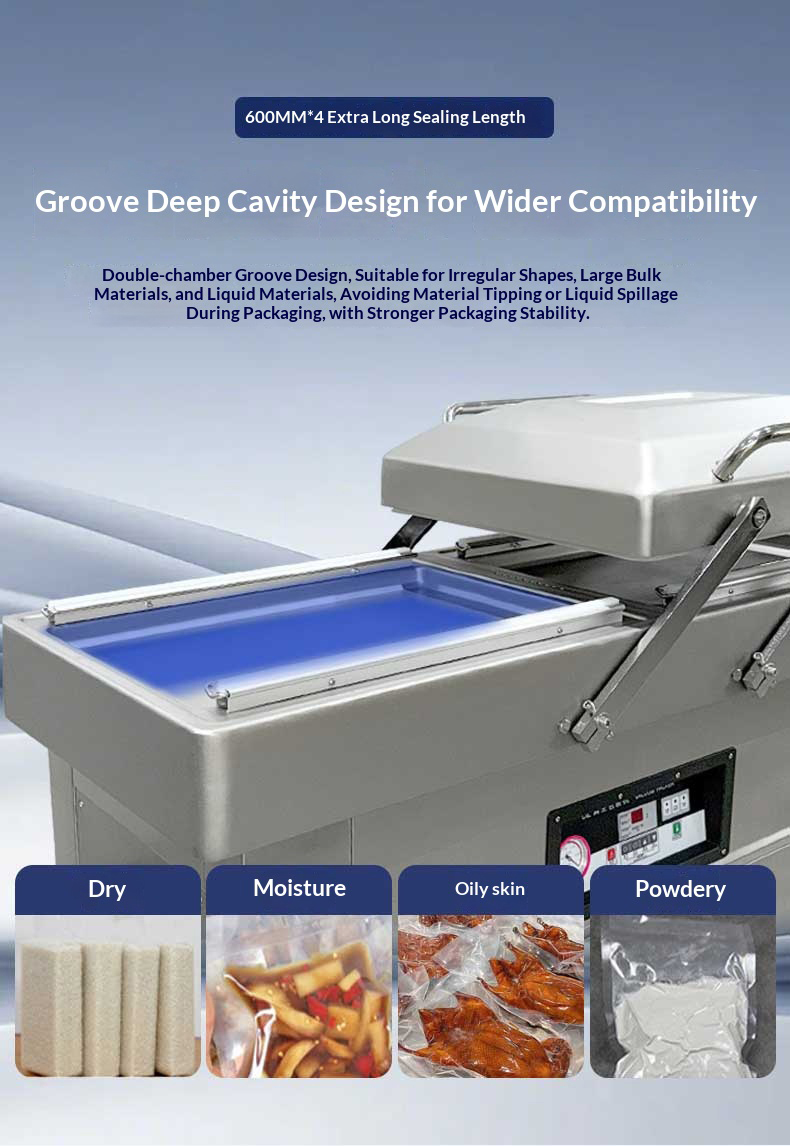

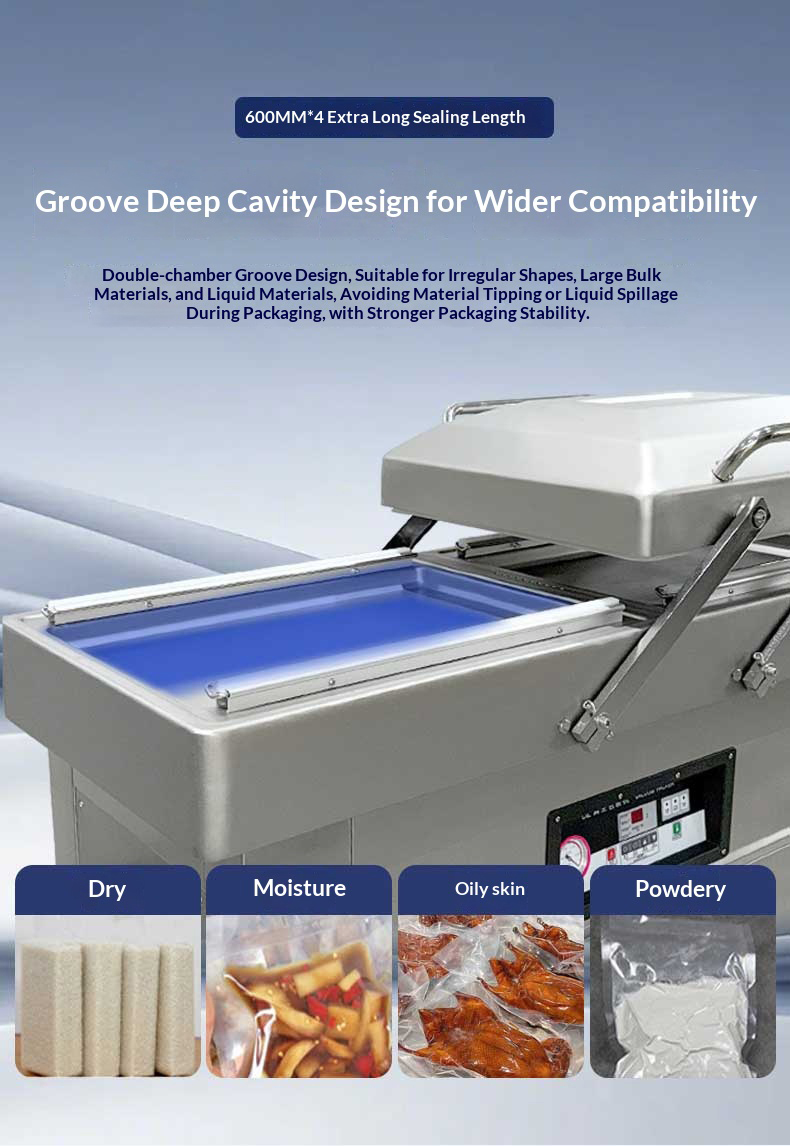

Suitable for products with soup or liquid : The concave design keeps the product in an inclined state during the packaging process, which effectively prevents soup or liquid from spilling during vacuum extraction and ensures sealing quality.

Adjustable concave size : The depth and style of the concave part can be adjusted according to specific requirements such as product height and shape, to achieve a more ideal packaging effect.

Dual-chamber design : While one vacuum chamber is performing vacuum extraction, the other can be used for placing packages. The alternating operation saves operation time and improves packaging efficiency.

Easy operation : It usually adopts a microcomputer control system. Users only need to set the vacuuming time and sealing time, then close the vacuum chamber cover, and the machine will automatically complete the entire vacuum packaging process.

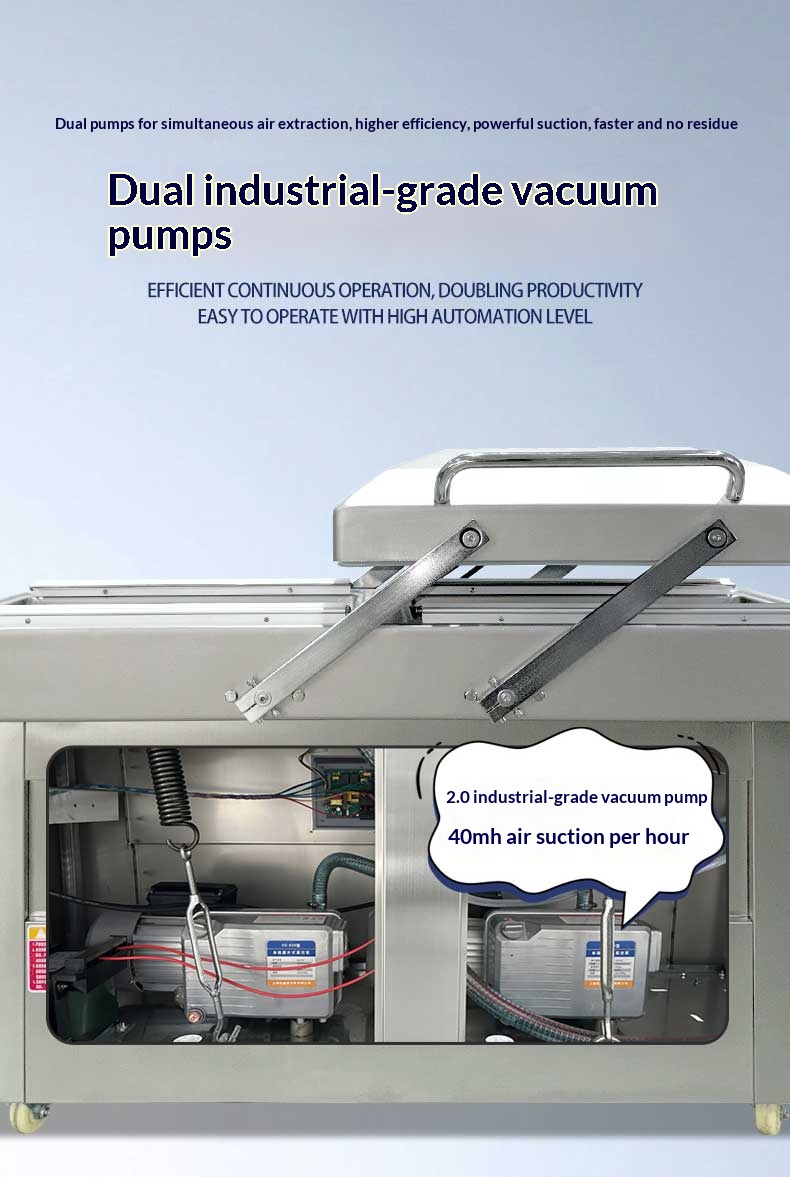

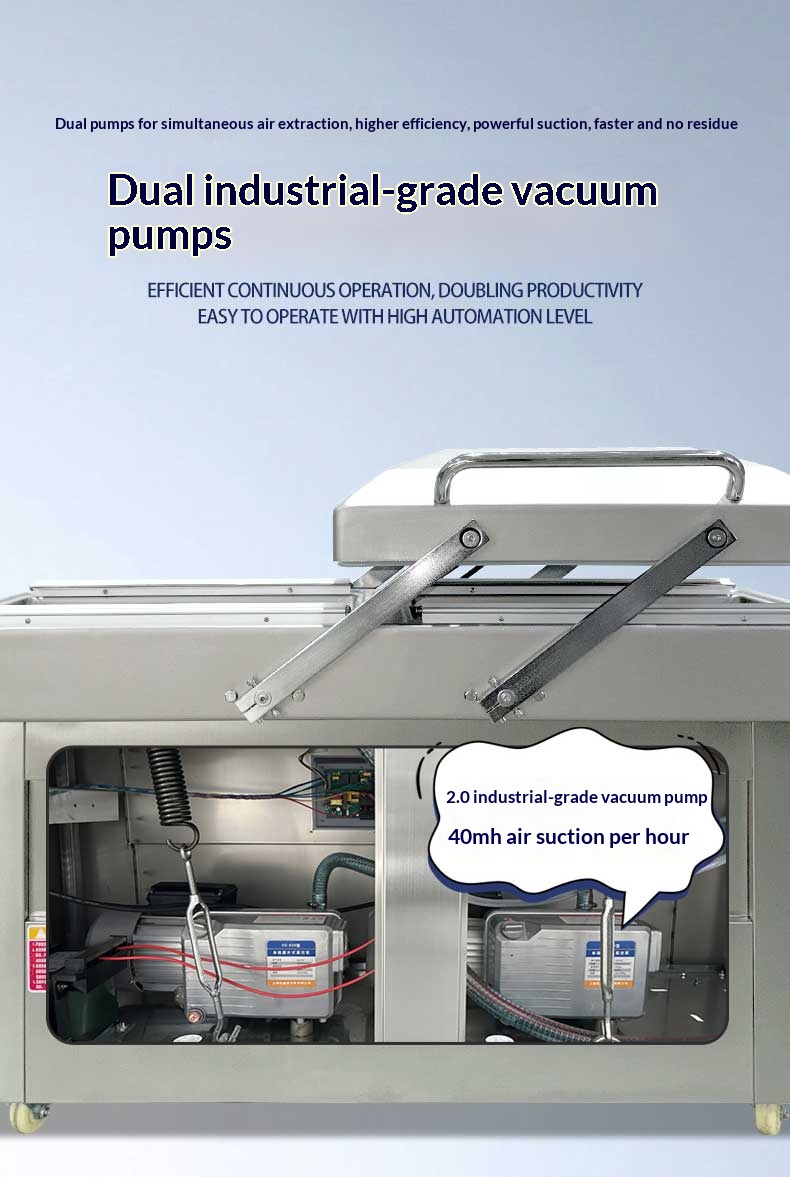

High vacuum level : Equipped with a high-power vacuum pump, it can achieve a high vacuum level in the packaging bag in a short time, effectively extending the storage or fresh-keeping period of products.

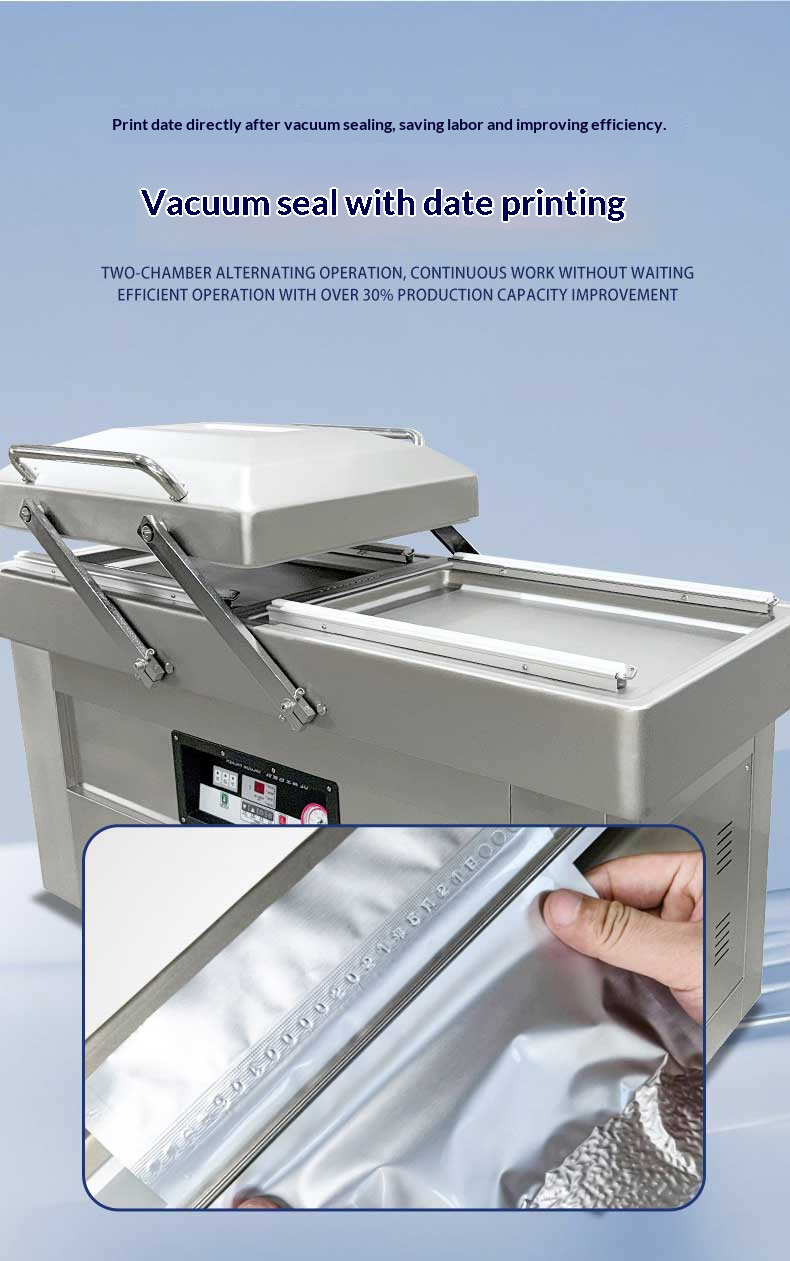

Excellent sealing effect : The heating strips and silicone strips are processed to be inclined, making the seal more neat and smooth, and ensuring the firmness and tightness of the seal.

High-quality main material : The main structure of the vacuum machine is generally made of stainless steel, which has good corrosion resistance and strength, and can maintain the stable operation of the equipment for a long time.

The double-chamber grooved vacuum packaging machine is specially designed for products with soup and high moisture content such as marinated food, aquatic products and prepared dishes. The innovative concave vacuum chamber structure combined with the dual-chamber alternating operation mode not only solves the problem of liquid leakage during packaging, but also greatly improves production efficiency. It is a powerful equipment for food processing and fresh-keeping of fresh products.

The whole machine body is made of stainless steel, which is corrosion-resistant, rust-proof and easy to clean, suitable for the humid operating environment of food workshops and durable for long-term use. With a high-power vacuum pump as the core component, it can reach a vacuum level of -0.1MPa with fast air extraction speed, which can quickly extract air from the packaging bag, effectively inhibit bacterial growth, and extend the fresh-keeping period and storage and transportation stability of products.

The depth of the concave vacuum chamber supports customization. After the product is placed, it is in an inclined state. During vacuum extraction, the soup is firmly locked in the groove and will not flow to the sealing area; the inclined heating strips and silicone strips fit closely, ensuring a flat and firm seal and eliminating the problem of sealing leakage. The dual-chamber independent operation design allows one chamber to perform vacuuming and sealing while the other can place products to be packaged synchronously, realizing seamless connection without idle time, and improving packaging efficiency by more than 50% compared with single-chamber models.

In terms of operation, it is equipped with a microcomputer control system. Users can set the vacuum time and sealing time with one key, and can get started without professional training, reducing labor costs. In addition to liquid-containing food, it is also compatible with the packaging of solid products such as nuts, dried goods and hardware electronic components, realizing multi-purpose use and meeting the production needs of various categories.

Applicable for food processing enterprises, fresh e-commerce warehouses, prepared dish factories, marinated cooked food stores, hardware and electronic parts factories, etc.